Project Description

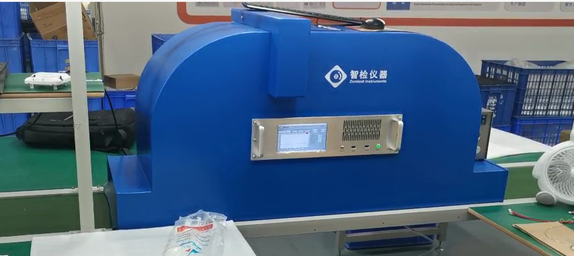

Production Line Test Smoke Tunnel

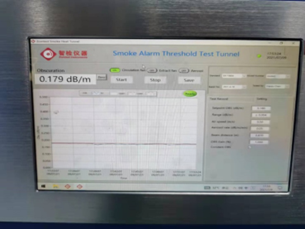

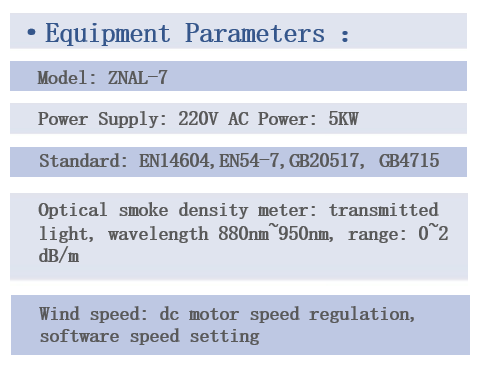

Flowline smoke box is used for batch test or calibration in the production of smoke alarm and detector. It adopts the same smoke generator and smoke density meter as the standard smoke box, which is composed of the main body of the smoke box, smoke density meter and industrial control computer. According to the requirements of standard specifications and parameters, it has its own photoelectric sensor, which is used to detect the smoke concentration value in the smoke body. The original imported components are used to ensure the accuracy and stability of the test. Intelligent PID control software is used to control the smoke concentration in the smoke box, so that the smoke concentration dB/m value is kept within a constant range. The smoke box of the assembly line is installed on the assembly line, and the alarms are placed on the conveyor belt and flow into the smoke box. After passing the smoke box, the state of the alarms is checked, and the batch rapid smoke alarms can be used for batch detection or sensitivity calibration. The specially developed Zomtest Smoke Test Tunnel software provides constant Smoke control and continuous monitoring of Smoke concentration. The conveyor belt speed can be adjusted according to the sensor response time to improve production efficiency.

Pipeline smoke box can be customized according to customer requirements of different trays or conveyor belt. continuously monitors Smoke attempts.

Device display